Integrated Supply Chain Planning – The Number 1 Opportunity

Enchange Supply Chain Consultancy

APRIL 7, 2014

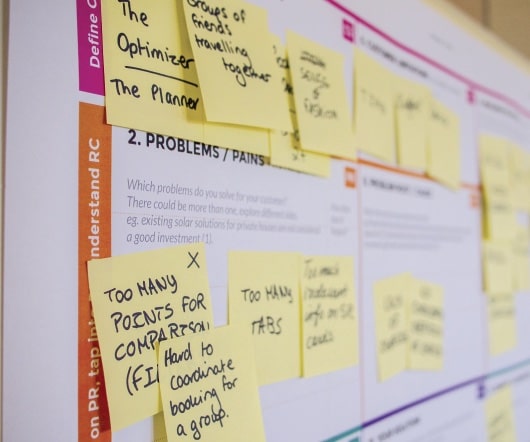

planning, sourcing, manufacturing, etc.) up to the point that finished goods are in the producers’ warehouse before the stock is sold to customers. By “route to market”, we mean the processes by which finished goods leave the warehouse and arrive on retailers’ shelves, often via third party distributors. So we held a workshop.

Let's personalize your content