Schneider Electric’s Supply Chain Design Journey

Logistics Viewpoints

NOVEMBER 18, 2024

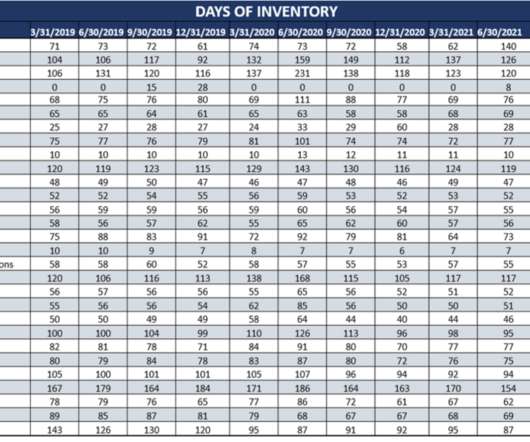

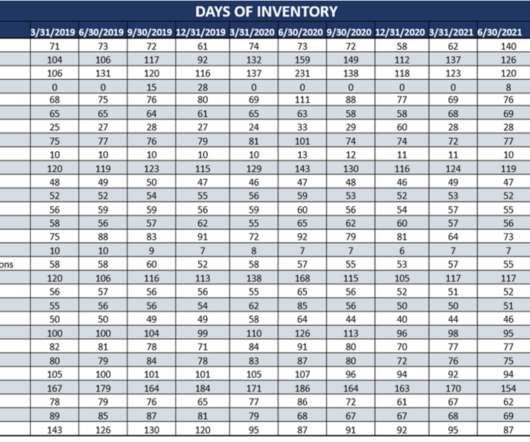

These facilities produce and ship 150,000 order lines per day. Schneider Electric’s Journey with Network Design Lee Botham is the global director of modeling and network design at Schneider Electric. Collaboration is a Critical Skill for Network Design Mr. Botham pointed out that not all projects generate results.

Let's personalize your content