25 Lean Manufacturing Tools – 5S, Six Sigma & Beyond

Unleashed

MARCH 24, 2024

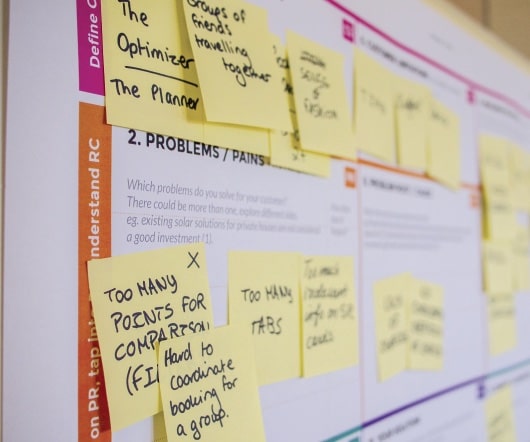

Lean Six Sigma Six Sigma is a set of methodologies first devised by Motorola in the 1980s, designed to improve the quality of Motorola’s products to the point where defects were so rare as to be statistically insignificant. When combined with lean practices, it becomes Lean Six Sigma. Inventory turnover.

Let's personalize your content