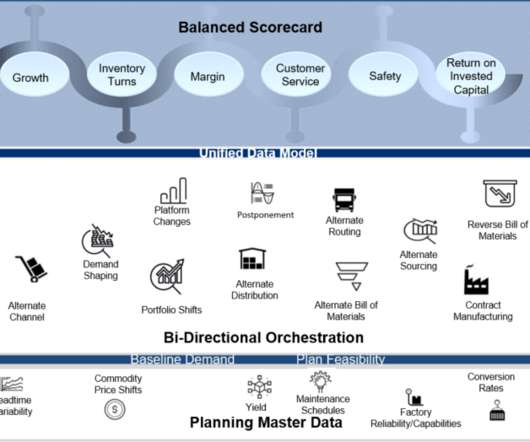

Aligning Supply Chain Metrics to Improve Value

Supply Chain Shaman

MAY 21, 2024

In follow-up qualitative interviews, one of the largest issues with organizational alignment was metric definition and a clear definition of supply chain excellence. In my post Mea Culpa, I reference my work with the Gartner Supply Chain Hierarchy of Metrics. Error is error, but is it the most important metric? My answer is no.

Let's personalize your content