Managing Supply Chain Disruptions: U.S., U.K. Manufacturers Accelerate Procurement

ivalua

JULY 14, 2022

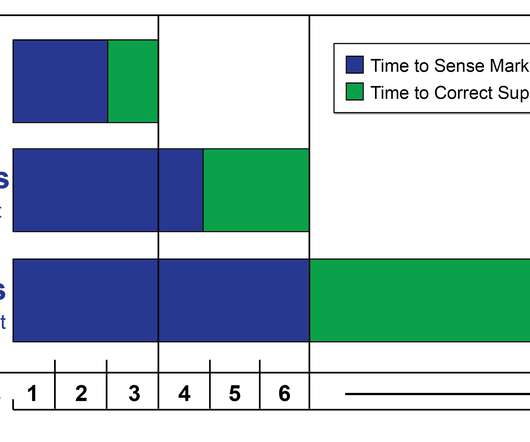

Ivalua study finds 97% of procurement leaders see significant disruption in direct materials supply chain; 67% not confident in existing technology; 84% consider modernization a ‘strategic priority’. Technology Advantage: 76% of manufacturing procurement leaders use supplier management software to optimize supplier relationships.

Let's personalize your content