S&OP: Should Not Be a Hammer Seeking a Nail

Supply Chain Shaman

MAY 9, 2023

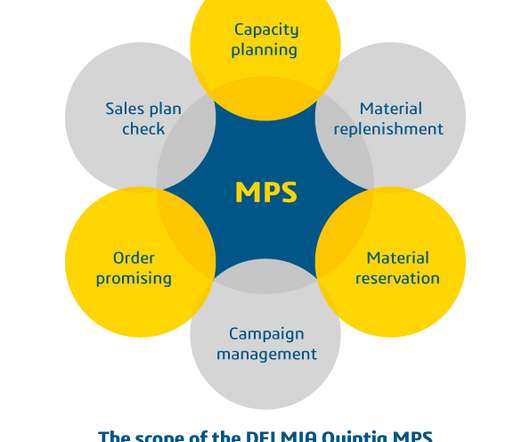

Organizations use S&OP as a hammer in search of a nail. The panel group is sourced from my group of LinkedIn followers. Supply Chain Center of Excellence Let’s start with a discussion on Supply Chain Centers of Excellence. As a result, I find the concept of S&OP over-used. It is not a panacea.

Let's personalize your content