Network Design in supply Chain

20Cube Logistics

APRIL 16, 2022

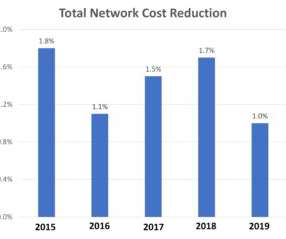

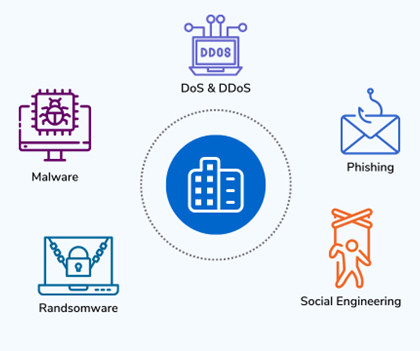

Supply chain Network Design can be explained as the strategic planning of the supply chain in order to measure the cost and the time required to bring the goods and services from manufacturers and suppliers to the market. Procurement costs and processes. Importance of network design in supply chain.

Let's personalize your content