Active Supply Chain Design: A Key Imperative for De Risking Supply Chains

Logistics Viewpoints

SEPTEMBER 19, 2023

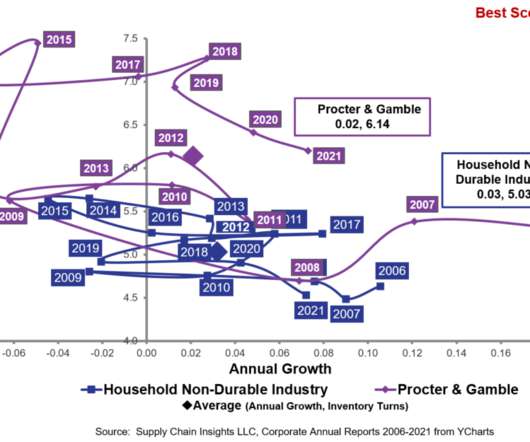

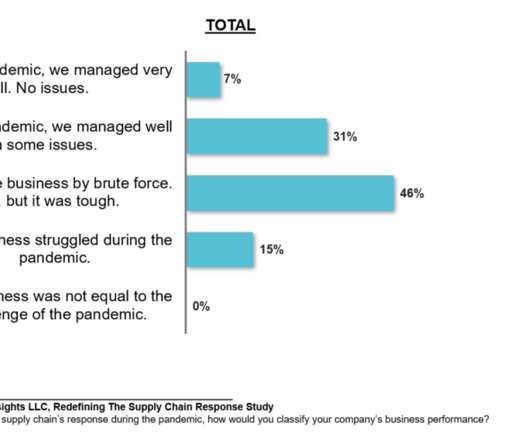

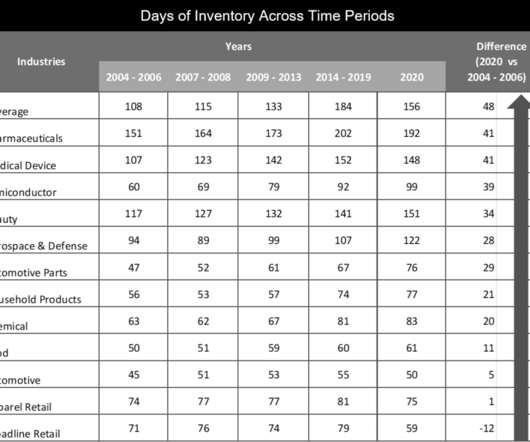

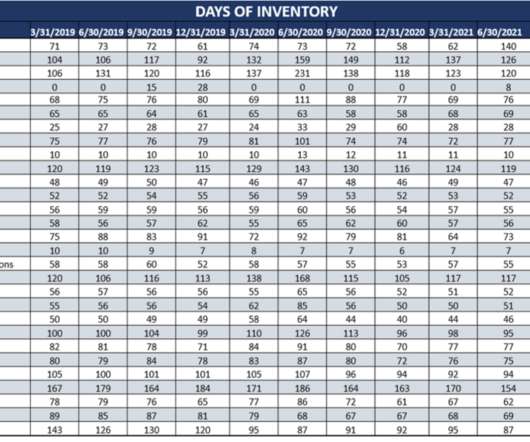

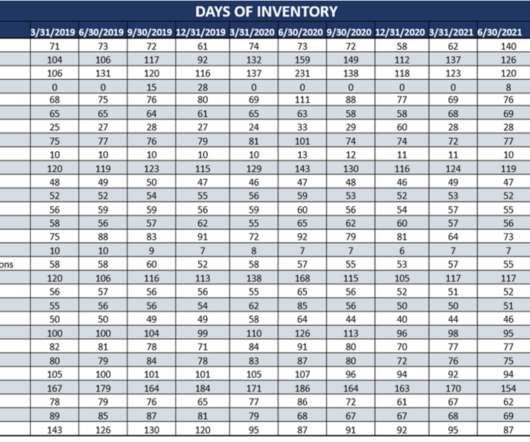

Supply chain executives must evolve from cost and service as the key objectives for optimal demand-supply balancing towards the “quadfecta” of cost, service, resiliency, and sustainability. Metrics such as lead-times, forecast accuracy, inventory levels, and service are used to measure operational risks.

Let's personalize your content