5 Recommendations towards a Resilient S&OP

Logistics Viewpoints

JULY 22, 2021

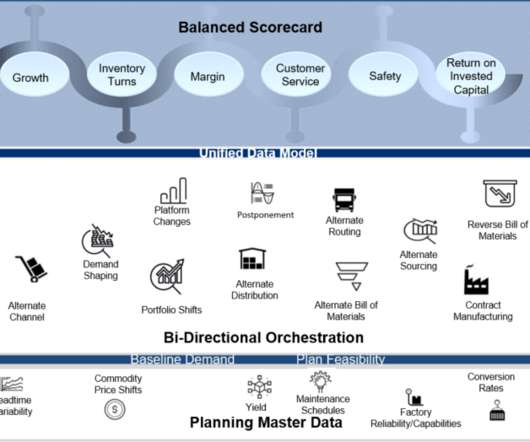

Sales & Operations Planning (S&OP) as a process has been around since the 1980’s. While the terminology evolved, the underlying thesis of S&OP has stayed the same, i.e., bridge the divide between sales forecasts and operational plans while respecting the budget.

Let's personalize your content