The Case for Real-Time Perpetual Inventory Signals in Manufacturing

ToolsGroup

JUNE 2, 2023

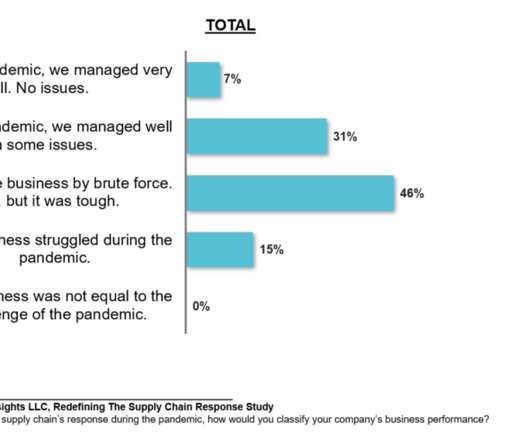

Once upon a time, the world of manufacturing was a relatively stable place. So how does a manufacturer navigate this rollercoaster? According to Gartner , these issues can lead to missed manufacturing deadlines and wasted capital. According to Gartner , these issues can lead to missed manufacturing deadlines and wasted capital.

Let's personalize your content