Lean Six Sigma for SMEs: A Path to Continuous Improvement

SCMDOJO

FEBRUARY 19, 2024

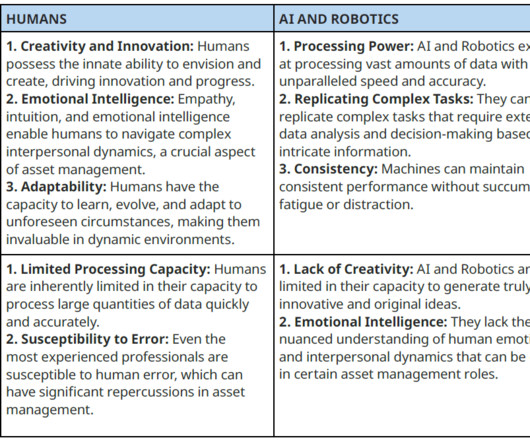

Over the years, various methodologies have emerged to address this need, including lean manufacturing, Six Sigma, and the integration of both known as Lean Six Sigma (LSS). Understanding Lean and Six Sigma Lean and Six Sigma are two powerful methodologies aimed at enhancing organizational efficiency and quality.

Let's personalize your content