Thirteen Years a Blogger

Supply Chain Shaman

FEBRUARY 4, 2025

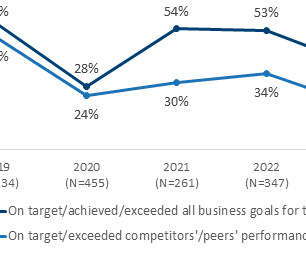

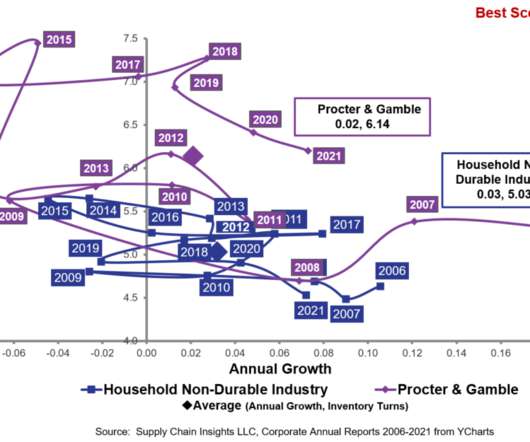

Despite the evolution of technology, none of the 28 industry segments I follow can drive improvement at the intersection of operating margin and inventory turns. We paused publishing the report this year while we worked with Georgia Tech on the right balance of metrics to drive market capitalization/employee. Change is Hard.

Let's personalize your content