Inventory Everywhere, But Not the Right Product to Ship

Supply Chain Shaman

MARCH 21, 2023

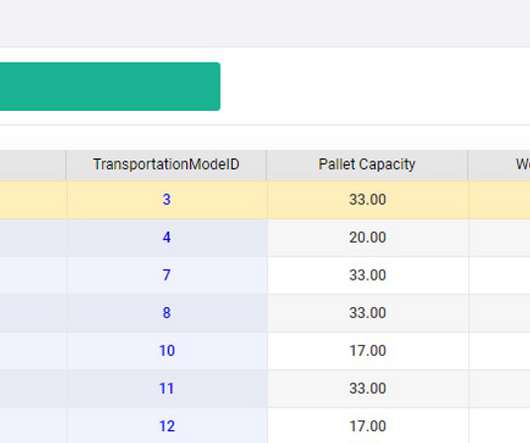

Bloated inventories. Despite investments in planning, today, industries hold 28 more days of inventory than in 2004. The larger the number of days of inventory, the greater the cash drag.) Changes in Inventory Year-end inventory values by industry from Y Charts. The story continues. Rising inflation. Next steps?

Let's personalize your content