Do No Harm…

Supply Chain Shaman

JUNE 16, 2014

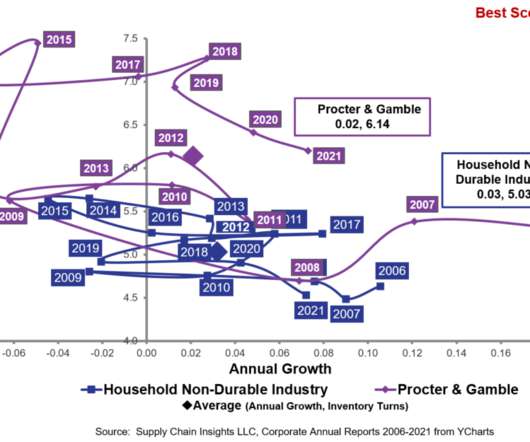

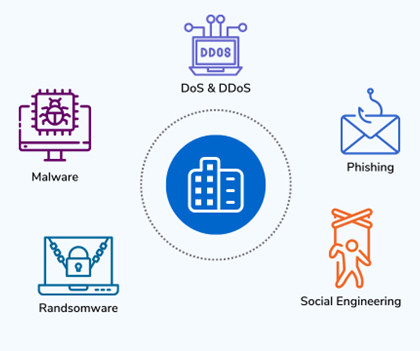

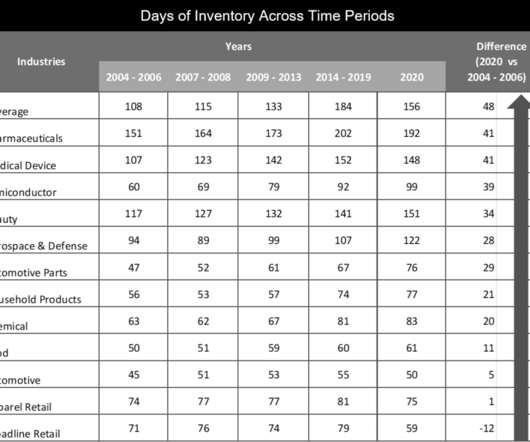

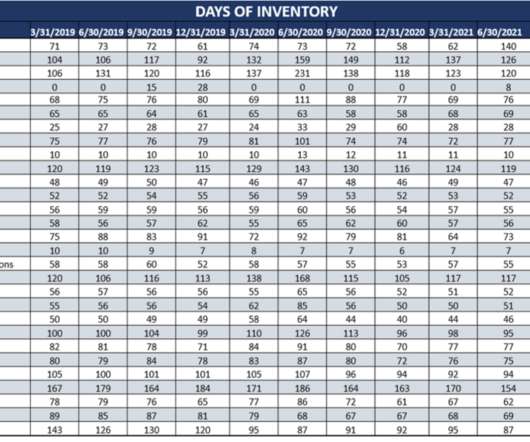

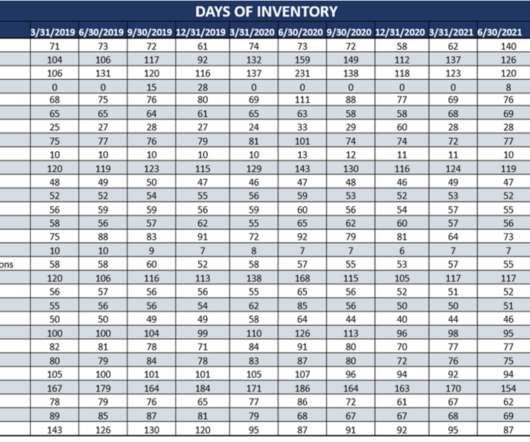

Despite two decades of advancement in supply chain technologies, companies are struggling to gain balance at the intersection of operating margin, inventory turns and case fulfillment. My goal is to understand the impact of technologies and processes. Today, we have a number of burning platforms. They are slow to adapt.

Let's personalize your content