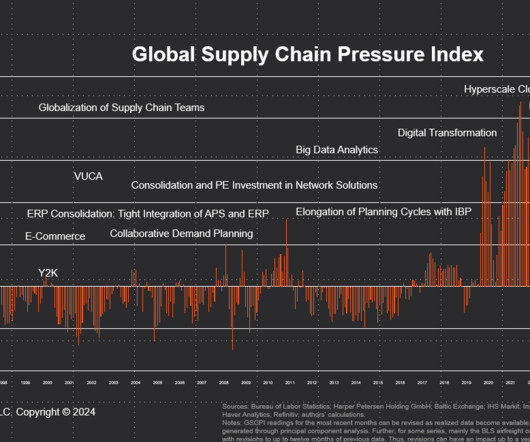

Why It Matters

Supply Chain Shaman

OCTOBER 1, 2013

Both companies provide packaging materials to the food manufacturing industry. Food manufacturers, over the course of the last decade, have pushed costs and waste backwards in the supply chain. billion company, manufactures glass containers with headquarters in the Midwest. Here I contrast their results. So, what can we learn?

Let's personalize your content