Reshoring to the US and Europe Accelerating, Now Also Serving CO2 Emission Reduction Objectives

The Logistics & Supply Chain Management Society

NOVEMBER 25, 2023

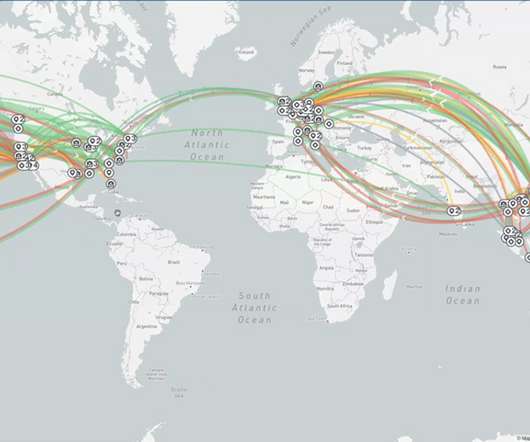

Reshoring to the US and Europe Accelerating, Now Also Serving CO2 Emission Reduction Objectives by Luc Kremers , Vice President – Asia Pacific, BCI Global Reshoring is accelerating as American and European companies want to de-risk their supply chains from geopolitical developments and supply chain disruptions.

Let's personalize your content