Supply Chain Resilience. Really?

Supply Chain Shaman

DECEMBER 7, 2023

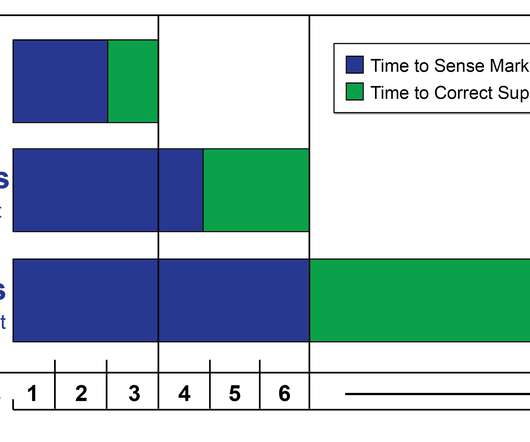

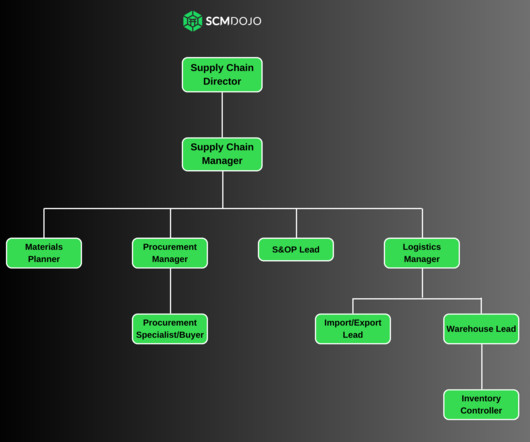

I believe that the ASCM definition is too reactive and rooted in the traditional, and outdated concepts on risk management. I am currently doing research on inventory management. In the research, I ask inventory planners to define resilience. Is this a risk to resilience? Today, this is not the case.

Let's personalize your content