Outside-in Process Q&A

Supply Chain Shaman

FEBRUARY 26, 2024

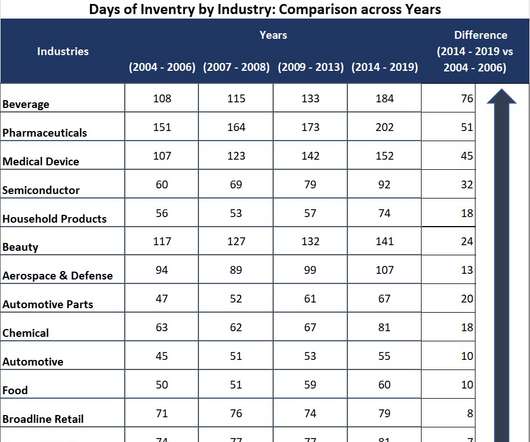

The company aligns channel requirements with available donors and successfully drives bi-directional orchestration programs to manage the reverse bill of materials (red cells and plasma) and demand-shaping campaigns to drive the right donors to the blood drives based on inventory levels. Analyze inventory health.

Let's personalize your content