You Should Be Worried. Supply Chains Are Not OK. Let’s Lock Arms To Drive Change

Supply Chain Shaman

DECEMBER 30, 2021

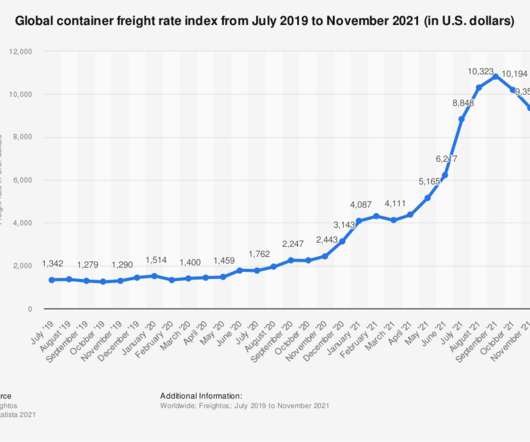

Background on Ocean Transport. Pandemic demand for goods, and the shifts from a service economy, increased volume in southern California ports where 40% of ocean carriers unload for entry into the United States. The landlocked ports of Southern California are especially problematic. We are awash in a sea of self-interest.

Let's personalize your content