How food and beverage manufacturers can reduce costs and improve profits

SYSPRO Smarter ERP

MARCH 14, 2022

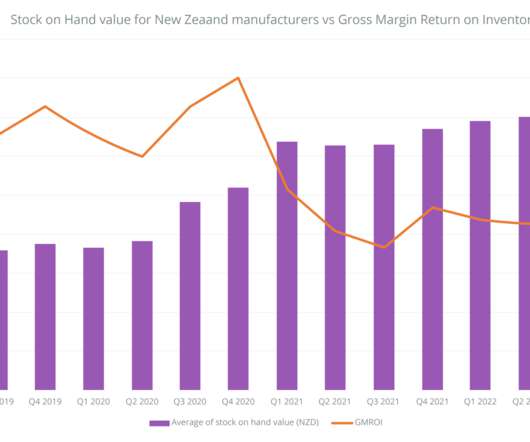

Food and beverage manufacturing and distribution companies usually operate on smaller margins than most organizations in other industries. Unfortunately, a significant chunk of food and beverage companies’ raw materials are commodities, whose prices don’t just fluctuate from month to month but can change hour-by-hour.

Let's personalize your content